Case Study on the Use of Polyacrylamide in Drilling Fluids

Abstract:

Drilling operations face challenges such as poor colloidal stability in drilling fluids, which can affect the efficiency and safety of the process. This case study introduces the application of polyacrylamide (PAM) in drilling fluids to address these issues and enhance the overall performance of drilling operations.

Introduction:

In the oil and gas industry, maintaining the stability and efficiency of drilling fluids is crucial for successful drilling operations. Colloidal instability can lead to various problems, including filter cake formation, fluid loss, and wellbore instability. Polyacrylamide (PAM), known for its excellent flocculating properties, has been widely used to improve the stability of drilling fluids .

Problem Addressed:

The primary issue in this case is the poor colloidal stability of drilling fluids, which can compromise the drilling process. Colloidal instability can lead to the formation of filter cakes that block pores and reduce permeability, affecting production rates .

Solution:

Polyacrylamide (PAM) is introduced as a solution to improve the stability of drilling fluids. PAM, with its high molecular weight and ability to form bridges between particles, effectively enhances the stability of drilling fluids. It is available in both colloidal and powder forms, is odorless, non-corrosive, and soluble in water but not in organic solvents. The molecular weight of PAM ranges from 2 to 6 million, with the powder form reaching up to 9 million .

Treatment Effectiveness:

The use of PAM in drilling fluids has shown significant improvements in several aspects of drilling operations. PAM polymers have demonstrated effectiveness in reducing fluid loss, flocculation, shale inhibition, dilution, and plugging leaks during drilling . The addition of PAM contributes to an increase in viscosity and a decrease in fluid loss and filter cake thickness, enhancing the overall performance of the drilling fluid .

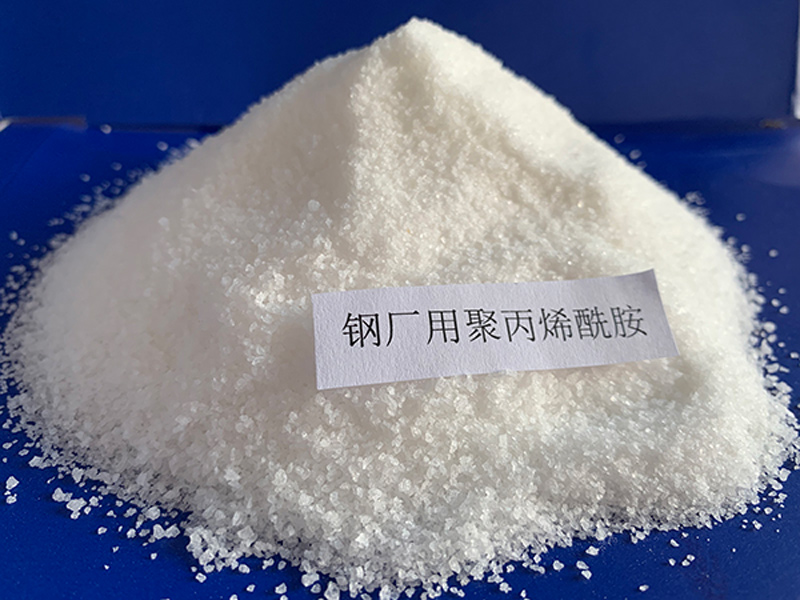

Product Description:

Polyacrylamide, coded as PAM, is a polymer typically structured with head-to-tail bonds of acrylamide monomers. It is available as a colorless, transparent, elastic colloidal liquid or as a white powder or flake solid. PAM is used primarily as a flocculant in polymer-free low-solids water-based drilling fluids and also improves the rheological properties of drilling fluids and reduces friction .

Applications of PAM in Drilling:

1. Cleaning the bottom of the well and carrying rock cuttings;

2. Cooling and lubricating the drill bit and drill string;

3. Forming a mud cake to protect the wellbore;

4. Controlling and balancing formation pressure;

5. Suspending rock cuttings and weighting agents;

6. Settling rock cuttings on the ground;

7. Providing information about the drilled formations;

8. Transmitting water power to the drill bit .

Conclusion:

The case study demonstrates that polyacrylamide (PAM) is an effective solution for improving the stability and performance of drilling fluids. Its use in drilling operations leads to better control over fluid loss, enhanced carrying capacity for rock cuttings, and overall improved drilling efficiency. PAM's versatility and effectiveness make it an indispensable component in the formulation of modern drilling fluids.