Textile Printing and Dyeing Factory Wastewater Treatment Case Study

Abstract:

The textile printing and dyeing industry is notorious for generating wastewater that contains difficult-to-degrade organic compounds such as phthalic acid esters and new types of assistants. This case study presents the effective use of polyacrylamide (PAM) in treating such wastewater, leading to compliant discharge standards.

Introduction:

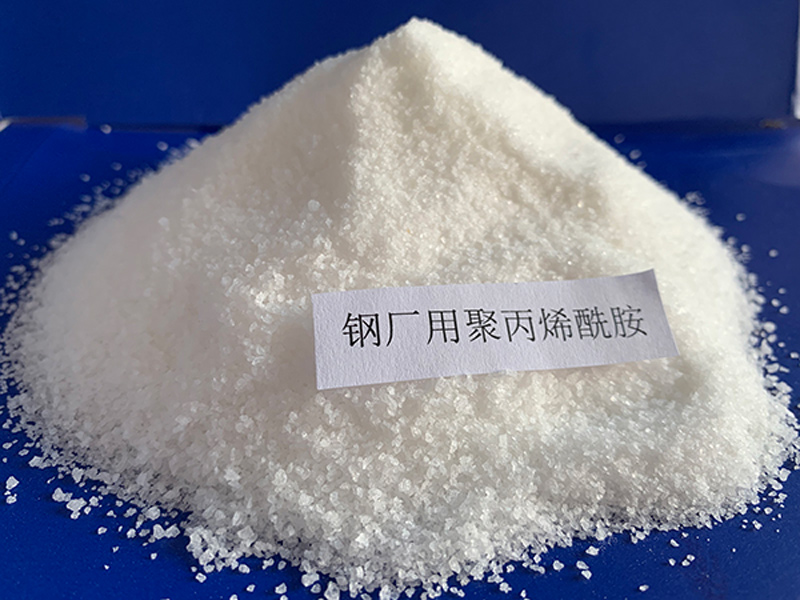

Textile printing and dyeing factories face significant challenges in managing wastewater due to the presence of non-biodegradable organic compounds. A common issue is the presence of phthalic acid esters and other assistants that are resistant to biodegradation. To address these pollution concerns, polyacrylamide derived from paper mills has been employed as a solution.

Treatment Process:

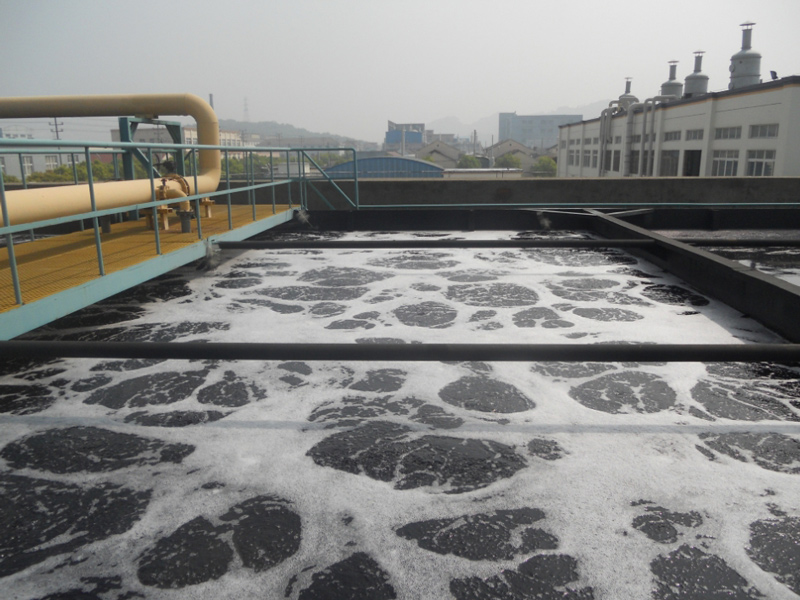

Polyacrylamide (PAM) possesses hygroscopic, flocculating, drag-reducing, and stabilizing properties. Its molecular chains can bridge and adsorb suspended particles in a solution, exhibiting a strong flocculating effect. In China, traditional methods such as large-area natural drying fields or incineration facilities are often impractical, especially in the Jiangsu and Zhejiang regions where the humid climate renders drying fields ineffective. Instead, small-scale wastewater treatment plants use PAM specifically designed for the printing and dyeing industry to achieve preliminary flocculation and sedimentation.

During the pre-treatment stage, anionic polyacrylamide is recommended for use due to its effectiveness in settling sludge. After preliminary conditioning, the sludge is dewatered using a press filter. In the dewatering process, cationic polyacrylamide is recommended as a dewatering agent for wastewater treatment in printing and dyeing factories. Cationic PAM effectively reduces the water content in sludge, leading to better dewatering results.

Conclusion:

The application of polyacrylamide in the treatment of wastewater from textile printing and dyeing factories has proven to be effective in China. It accelerates the sedimentation of sludge and aids in the pressurized filtration process, contributing to the high efficiency and economic operation of wastewater treatment. The appropriate selection of flocculants is crucial for enhancing the treatment of sludge water and ensuring the environmental sustainability of textile printing and dyeing operations.